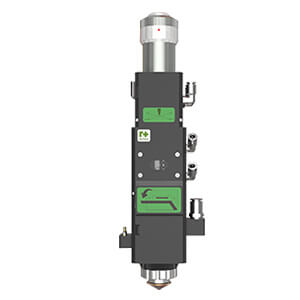

Raytools Laser Head Series

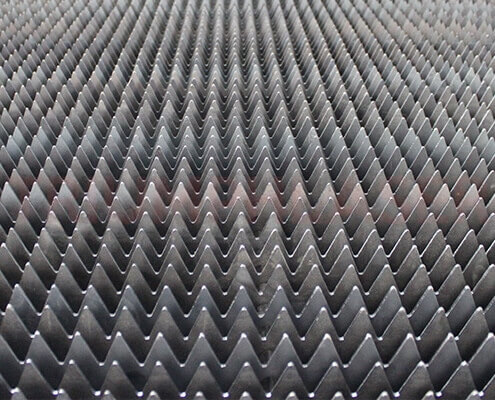

The laser head made in Swiss is suitable for fiber laser cutting machine, with a diversified interface setting so that it can be matched with all kinds of mainstream fiber lasers. The cutting head adopts the optimization of optical design, light weight, small volume, easy to use, with a height sensor can make cutting more efficient, but low price,which is preferred for cutting equipments with fiber laser cutting machine.

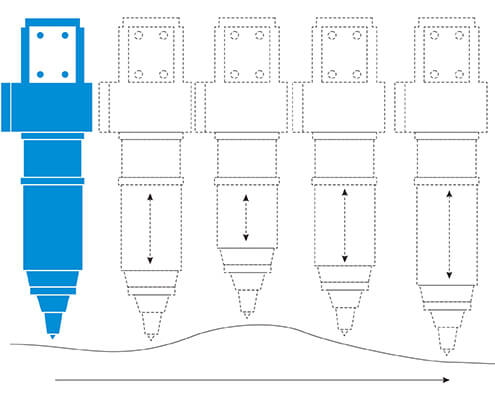

Auto – focus:Applicable to various focal lengths, which are controlled by machine tool control system. Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal.

Accuracy:Increasing perforation focus length, separately setting perforation focal length and cutting focal length, enhance cutting accuracy.

Raytools laser cutting head BT210S:(Rated Power)≤1500W

Raytools laser cutting head BM109:(Rated Power)1500W

Raytools laser cutting head BT240S:(Rated Power)3000W

Raytools laser cutting head BM114S:(Rated Power)6000W