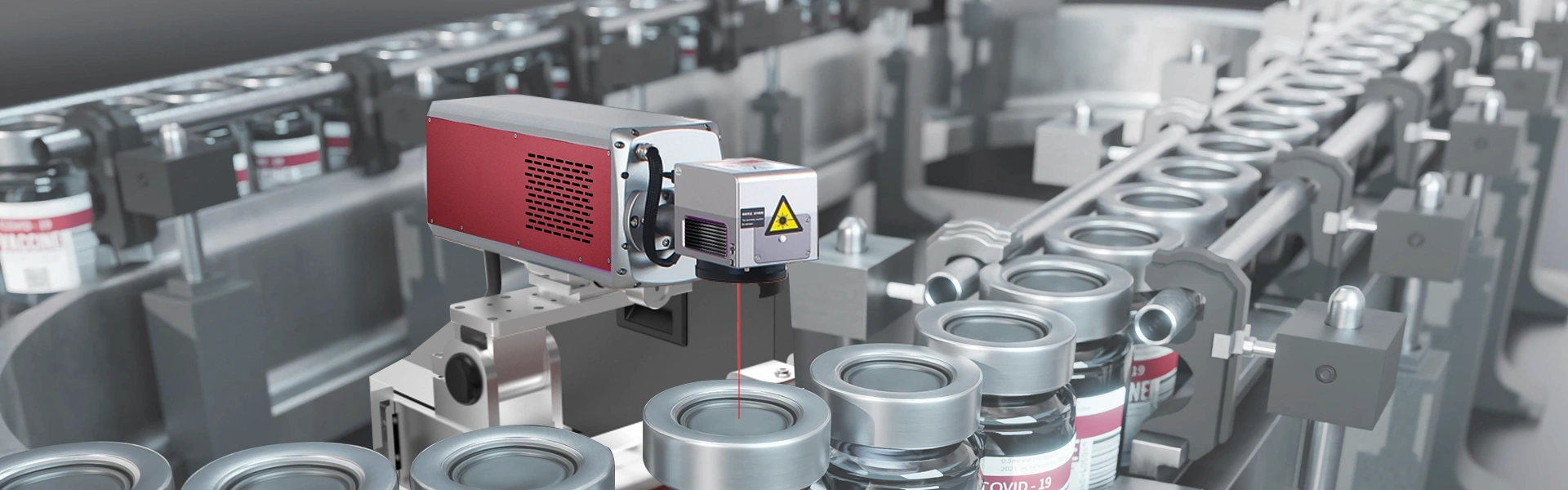

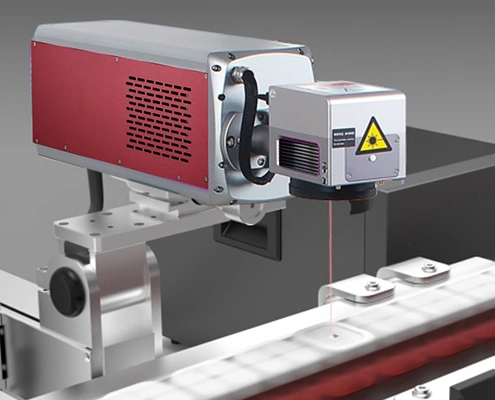

Fiber flight laser coding machine

Fiber optic flying laser printer is designed to improve productivity and high-speed continuous marking models, using the domestic first-line fiber optic optical device. Higher security, stable performance, fast processing efficiency, 100 3MM high 2D codes per minute, and 100 production date digital codes per minute, providing high-speed, high-volume applications of marking needs,mainly used in production date, anti-counterfeiting, pharmaceutical and food packaging industry. This model supports automatic coding, serial number, batch number, date, barcode, 2D code, automatic number skipping and other functions to meet the needs of customers in different industries.

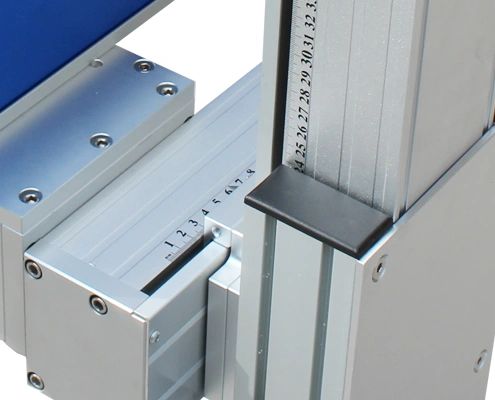

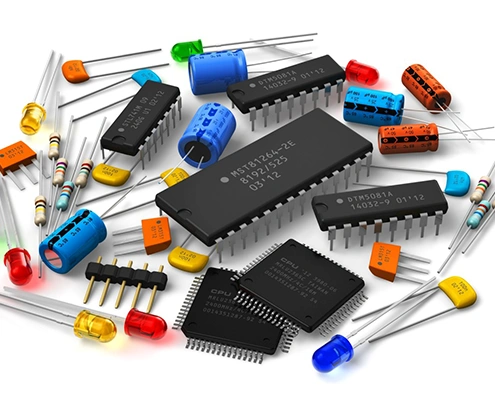

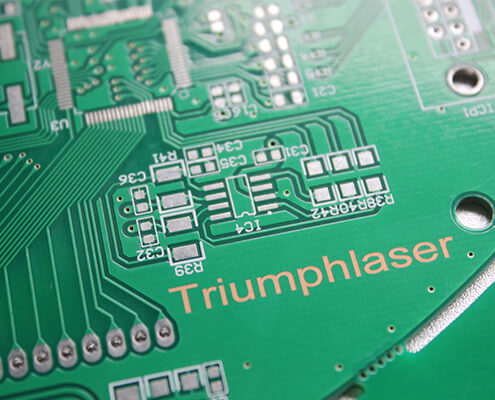

Fiber laser in-line marking machine is suitable for in-line marking of most metal materials and some surface treated non-metal materials, such as metal products, PVC, HDPE, aluminum film, rubber and plastic, etc. It is widely used in personal care products, food and beverage packaging, alcohol, dairy products, electronic components, chemical building materials products and other fields of production and effective date, batch number, shift, manufacturer name and logo and other graphic and text marking.

20W/30W/35W/55W

Marking speed200m/min

No consumables,long-term maintenance-free