Metal laser cutting application analysis

Laser manufacturing activities currently include cutting, welding, heat treating, cladding, vapor deposition, engraving, scribing, trimming, annealing, and shock hardening. Laser manufacturing processes compete both technically and economically with conventional and nonconventional manufacturing processes such as mechanical and thermal machining, arc welding, electrochemical, and electric discharge machining (EDM), abrasive water jet cutting, plasma cutting, and flame cutting.

Project description

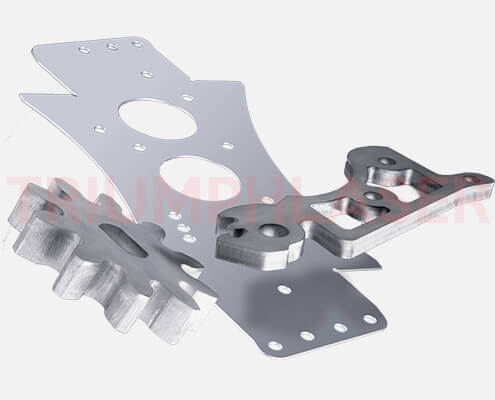

TIME SAVER:High pressure assist gas, such as oxygen or nitrogen is injected through the metal cutting nozzle. The result is a dross free cut edge which requires little to no deburring.

LOW OPERATING COST:Laser cutting is a non-contact process that eliminates the high costs of replacement die stamps, machine center re-tooling and router bits.

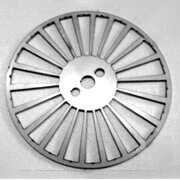

INTRICATE CUTTING: Metal laser cutting machines are capable of cutting thin gauge metal to shape. A beam of only 0.1mm allows for the most intricate designs to be cut.