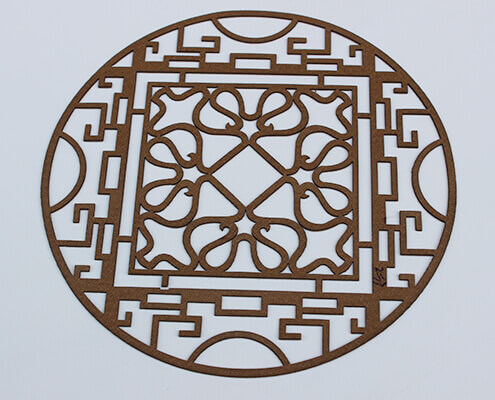

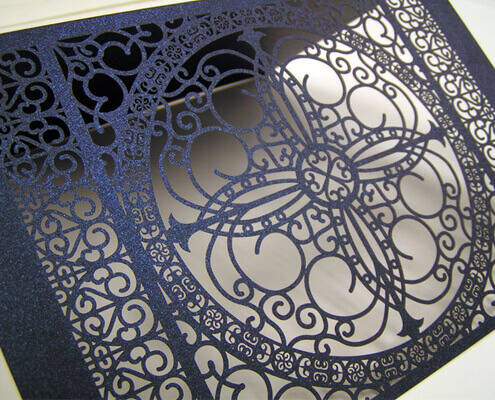

Leather&Fabric laser cut

Fabric is quickly becoming a very popular material for both engraving and cutting. Natural fibers, as well as synthetic fabrics, are often cut and engraved with fantastic results with a laser system

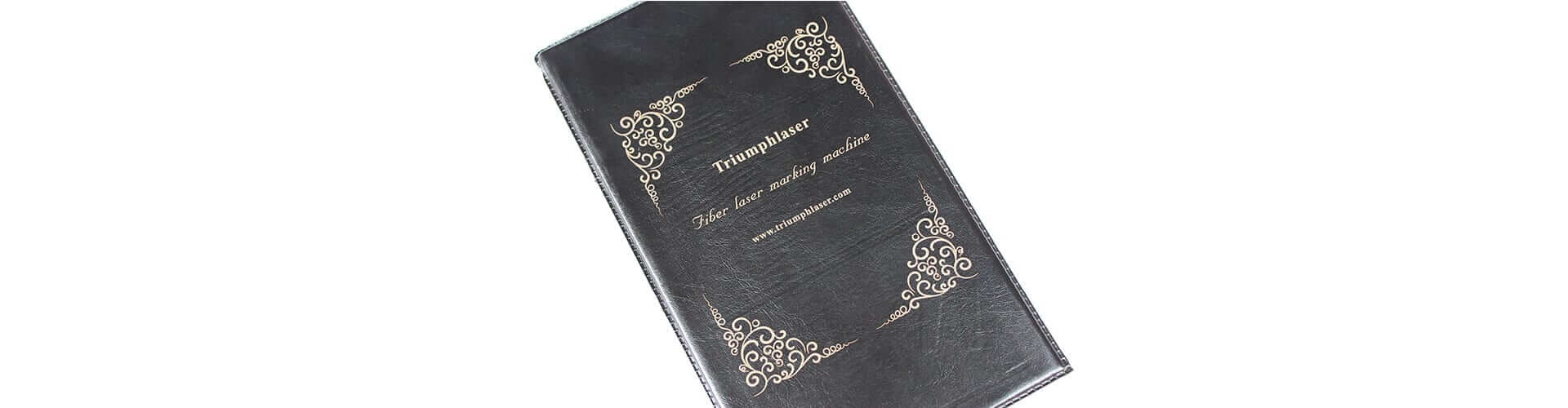

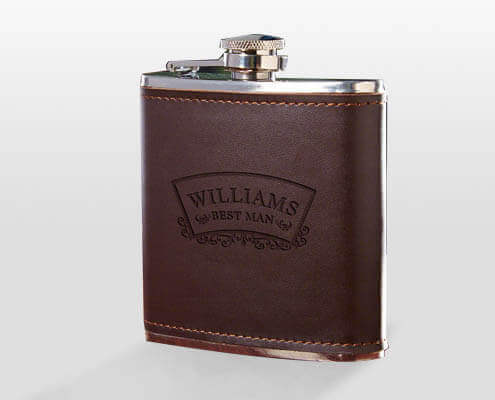

Leather is a wonderful material – and not just for clothing and fashion accessories!You can used leather to make a huge variety of products to gift and sell

Project description

Leather is a wonderful material – and not just for clothing and fashion accessories!

With a customized laser engraving machine, you can easily give leather a quality finish. With a Trotec laser, leather is engraved quickly and easily for purses, wallets, bracelets, belts, shoes and more.

Leather types suitable for laser engraving

Natural leather | Suede leather | Napped leather | Nubuck leather | Synthetic leather | Alcantara leather