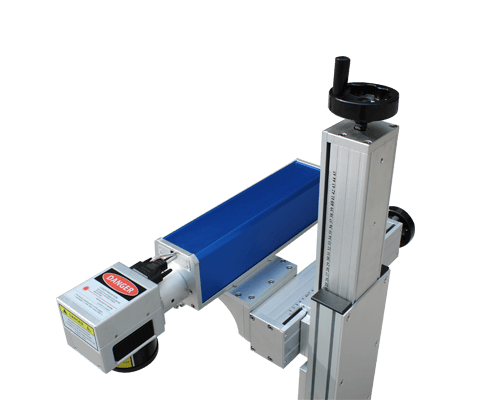

Flying Laser Marking Machine

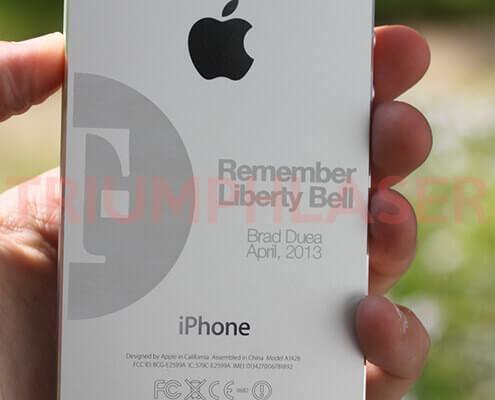

Fiber Laser marking machine TR-F20M adopts the third generation (the most advanced) solid-state fiber laser to create the super fine effect of marking. This model is compact structure, no pollution, no optical power coupling loss, air cooling, high efficiency and stability, its life is more than 100000 hours. Fiber Laser engraver output power:20W. The software is easy to use and can work with any content such as graphic,charters,letters,barcode,qrcode etc.It can widely used in various metal and some non-metallic surface to create the permanent mark.