How to improve the marking effect and speed of a laser marking machine

In today’s society, fiber laser marking machine is mainly used in metal materials for processing, and its marking content includes text, pattern, two-dimensional code, production date, etc., especially combined with the flight marking system, which can realize the processing and marking of assembly line mode, and is widely used in beverage bottle cap marking, wine bottles, battery products and other assembly line marking processing. So let’s analyze what factors can affect the laser marking effect and rate.

First of all, for fixed marking graphics, the factors that affect the marking efficiency can be divided into the equipment itself and the processing material.

Therefore, it can be concluded that the final factors that affect the marking efficiency are the type of filling, field mirror, galvanometer, time delay and other factors.

The second is how to improve the marking efficiency measures:

- Choose the most suitable of the four fillers;

- Two-way filling: marking efficiency and good effect.

- Paper-back filling: only when marking fine graphics and fonts will be used, and the efficiency is similar to that of bow filling.

- One-way filling: the marking efficiency is the slowest, and it is rarely used in actual processing.

- Bow filling: the marking efficiency is the highest, sometimes there will be connection lines, uneven problems, when marking fine graphics, fonts, the above problems will not occur, so bow filling is the first choice.

The above four filling methods are different, which can be changed according to the actual marking needs, and the corresponding filling methods can also improve the marking efficiency. If you do not pursue the marking effect of details, it is recommended to use bow filling to significantly improve the marking speed. If you want to have both, bidirectional filling is a good choice.

Second, choose its better high-speed galvanometer;

In general, the galvanometer scanning speed can reach up to 3000mm/s, but the better high-speed galvanometer can scan tens of thousands of times per second. In addition, when using a galvanometer to mark small graphics or fonts, they are prone to distortion, and it is necessary to reduce the scanning speed to ensure the effect.

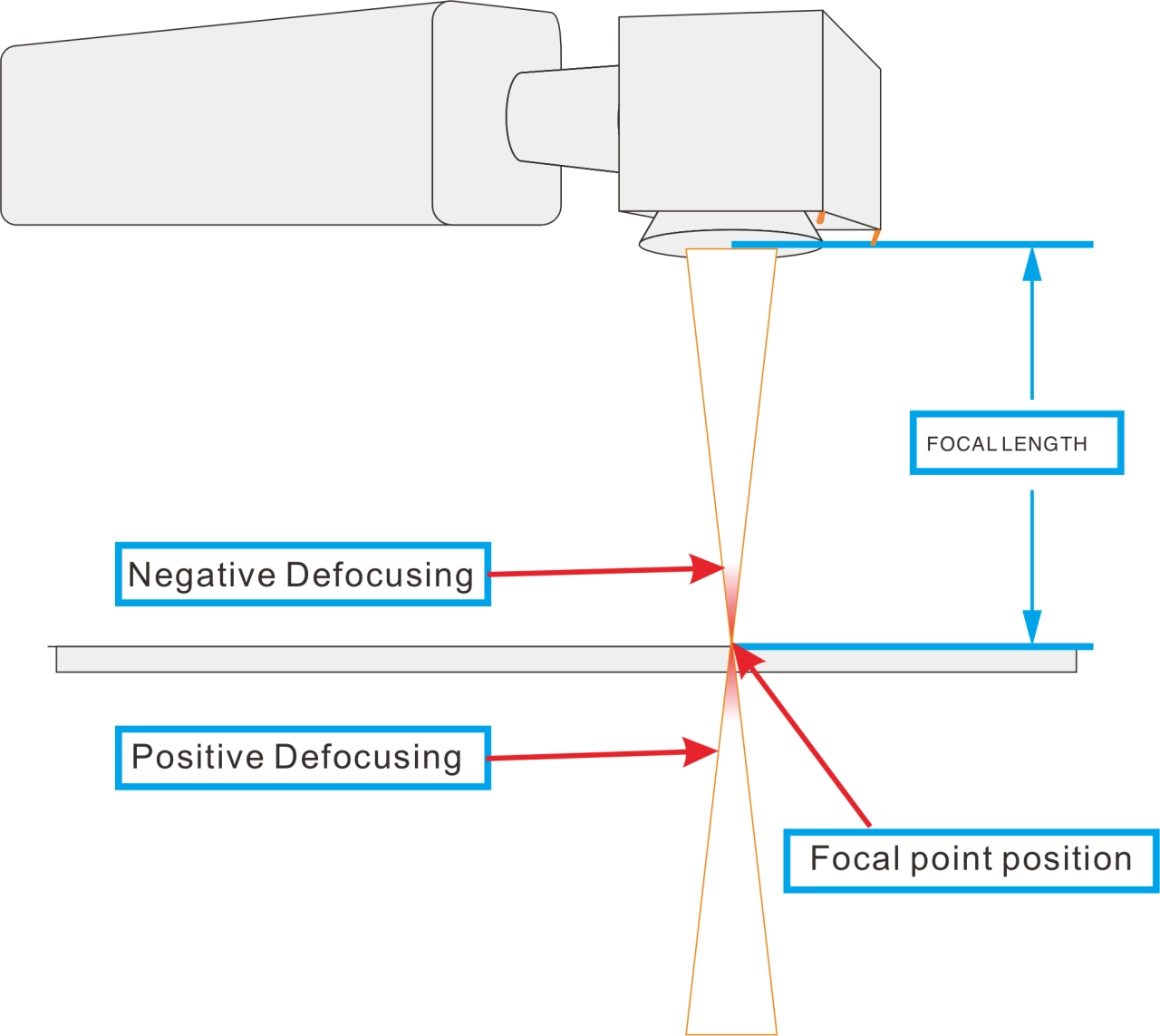

- Appropriate field mirror;

The larger the focal length of the field mirror, the larger the focused spot, and the same spot overlap rate, the spacing of the filling line can be increased, thereby improving the marking efficiency.

Note: The larger the field mirror, the smaller the power density, so it is necessary to increase the spacing of the fill line with sufficient marking energy.

Fourth, cleverly set the delay;

Different fill types are affected by different time delays, so reducing the time delay that is not related to that fill type can also improve marking efficiency.

- Bow filling and paper filling: It is mainly affected by the corner delay, which can reduce the opening delay, closing delay and ending delay.

- Two-way filling and one-way filling: It is mainly affected by the light opening delay and closing time delay, which can reduce the corner delay and end delay.

But at the same time, it should also be noted that thick graphics and fonts are less affected by the delay, and the delay can be appropriately reduced. Thin graphics and fonts are greatly affected by the delay, and the delay can be increased appropriately.

- Other channels;

- Check “Evenly distribute fill lines”.

- For the graphics and fonts with thick marking, you can remove the “enabling outline” and “spare the side once”.

- If the effect allows, you can increase the “jump speed” of “advanced” and reduce the “jump delay”.

- Marking a wide range of graphics, appropriately divided into several parts to fill, can effectively reduce the jump time, improve the marking efficiency.

The application of fiber laser marking machine requires certain application experience of technical personnel to participate in the operation, in order to better complete the good marking effect, at the same time, the fiber laser marking machine also needs to know how to maintain and clean the daily maintenance, understand the basic structure and structure, in order to improve the use of fiber laser marking machine.

This is Yolanda from triumphlaser If you want to learn more about laser marking machine, please don’t hesitate to contact with me.

Email:sales1@triumphlaser.com

triumphlaser

triumphlaser

triumphlaser

triumphlaser