Optimizing Fiber Laser Marking: The Importance of Focal Point

Fiber laser marking machines are widely acclaimed for their precision and efficiency in engraving and marking various materials. However, achieving the desired marking results requires a deep understanding of the laser’s focal point and its impact on the process.

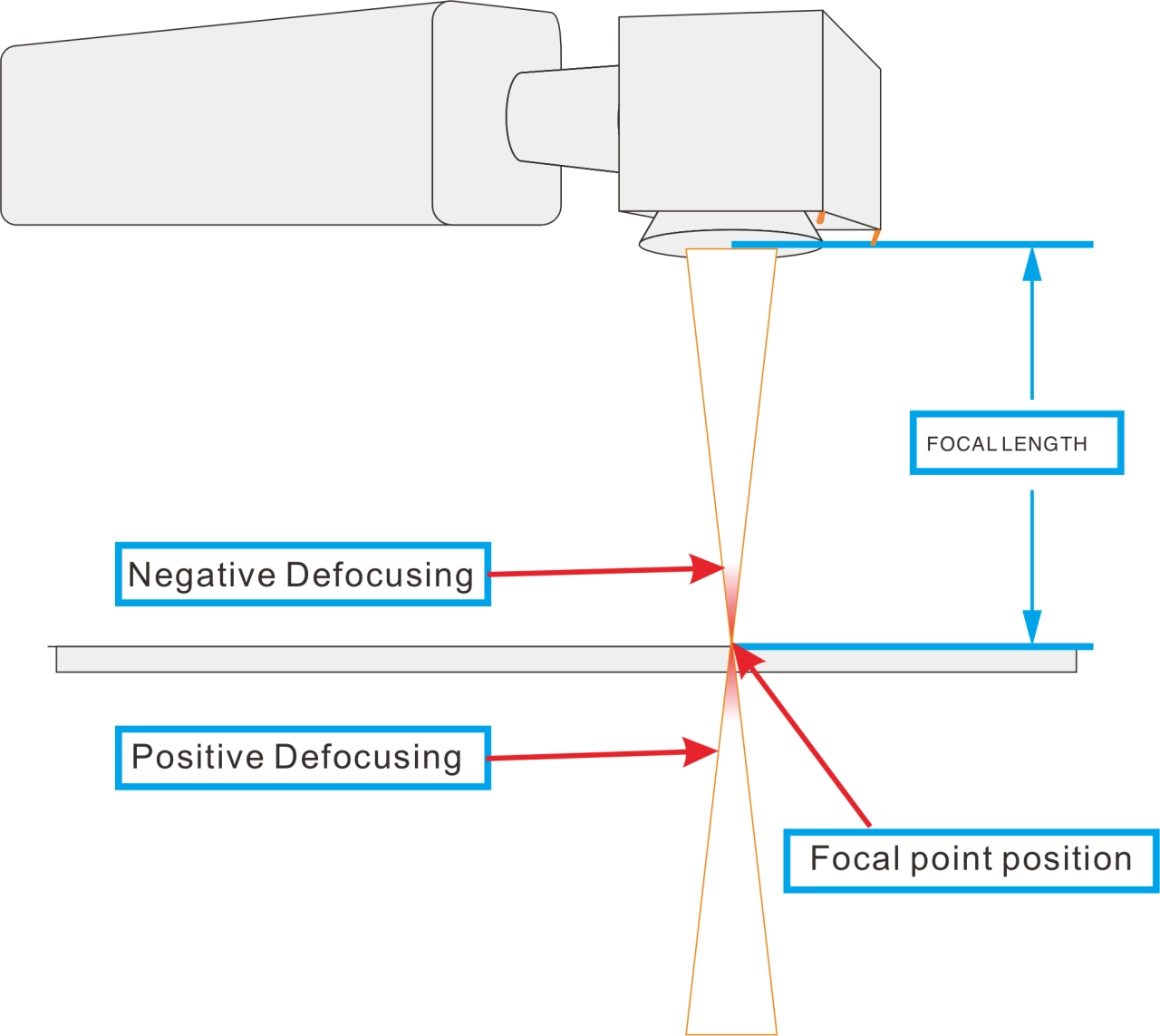

When it comes to fiber laser marking, both positive and negative defocusing can lead to a weakening of the laser beam. It’s crucial to understand that the strength of the laser beam is at its maximum only at the focal point.

Positive Defocusing: When the laser beam is positively defocused, meaning it is focused beyond the focal point, the beam diverges, spreading out over a larger area. This causes a reduction in the intensity of the laser beam, resulting in weaker marking performance. While positive defocusing can be advantageous for certain applications, such as surface annealing, it is essential to consider its impact on marking quality.

Negative Defocusing: Conversely, negative defocusing occurs when the laser beam is focused before reaching the focal point. In this case, the beam converges, leading to a similar reduction in beam intensity and weakening of the marking performance. Negative defocusing may be suitable for applications requiring broader marking coverage, but it also affects the clarity and precision of the markings.

The Importance of Focal Point: The focal point is the critical factor in fiber laser marking. It represents the optimal convergence of the laser beam, where the beam intensity is at its strongest. Achieving the correct focal point ensures the highest marking quality and precision.

Illustrating Positive and Negative Defocusing: In the attached images, you can see the positions of positive and negative defocusing relative to the focal point. These illustrations demonstrate how the beam weakens as it moves away from the focal point. By understanding these positions, operators can adjust the focal point to optimize marking performance.

Focal point position:The focal point position refers to the location where the light beam is focused to its smallest point. In optical systems, the focal point is typically achieved by adjusting the position of lenses or mirrors to converge the light rays to a single point. The position of the focal point determines the degree of light convergence and the size of the focal spot. For laser marking machines, ensuring that the laser beam is focused to the precise focal point position is crucial, as it directly affects the accuracy and quality of the marking.

In conclusion, mastering the focal point is essential for maximizing the performance of fiber laser marking machines. By ensuring the laser beam is focused precisely at the focal point, operators can achieve the highest quality and precision in their marking applications.

This is DAVID from triumphlaser If you want to learn more about laser welding machine, please don’t hesitate to contact with me.

Email:david@triumphlaser.com

triumphlaser

triumphlaser triumphlaser

triumphlaser