Triumph Fiber laser cutting machine evaluation

Triumphlaser fiber laser cutting machine uses the most advanced China Raycus fiber laser to output a high-energy density laser beam and focuses it on the surface of the workpiece, so that the area irradiated by the ultra-fine focus spot on the workpiece is instantly melted and vaporized, through the CNC mechanical system Move the spot irradiation position to realize automatic cutting. The fiber laser cutting machine adopts advanced technology and unique design, special inner cavity, to ensure the stable operation of the system and constant power. The cutting gap is uniform, and it is convenient to adjust the light and maintain. The closed optical path guides light to ensure the cleanliness and service life of the lens. It is a high-tech equipment that integrates the most advanced fiber laser technology, numerical control technology, and precision mechanical technology.

Advantages of TR-F1530 Fiber Laser Cutting Machine:

Beam quality: the focused spot is smaller, the cutting line is finer, the work efficiency is higher, and the processing quality is better;

Cutting speed: 2 times of the same power laser cutting machine;

Cost of use: The power consumption of the whole machine is about 30% of the traditional O2 laser cutting machine;

Maintenance cost: no laser working gas; optical fiber transmission, no need for reflective lenses; can save a lot of maintenance costs;

Product operation and maintenance are convenient: optical fiber transmission, no need to adjust the optical path;

Flexible light guide effect: small size, compact structure, easy to flexible processing requirements;

Large processing plate width: The processing plate width is increased from 3000×1500 to 4000×2000, so that customers can process large plates without worry;

1. The fiber laser cutting machine is equipped with a 750 watt Raycus laser, using Taiwan screw Yaskawa motor and driver.

2. Fiber laser cutting machine 4020 tube-sheet integrated machine meets the processing needs of plate and tube at the same time.

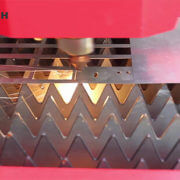

3. The fiber laser cutting machine, the plate and tube integrated machine cut various shapes of holes and patterns, bevel cutting and other metal processes for the tube to form the opening of the box body.

4. Fiber laser cutting machine has high photoelectric installation and replacement rate, extremely low operating cost, and optical path maintenance

The characteristics of fiber laser cutting machine are introduced:

1. Adopting advanced raytools fiber laser cutting head, fast and accurate focusing, easy to replace the drawer type protective lens, and anti-collision design can effectively avoid the loss of the laser head caused by uneven plate.

2. The long axis adopts dual-drive rack and pinion transmission (Swedish Linden pinion and pinion). The rack and pinion transmission improves the high-speed cutting ability of the equipment and can ensure the accuracy requirements of the equipment during high-speed cutting (cutting speed ≥ 25m/min) The dual-drive transmission has better balance, which makes the equipment run more smoothly and with higher precision.

3. The gear and rack lubrication adopts microcomputer control and automatic lubrication, no system control is needed to ensure that the gear and rack can be fully lubricated and protected at any time.

4. The gantry beam of the equipment is processed by integral cast aluminum. The cast aluminum beam is light in weight, and the weight is only 1/3 of the steel beam of the same volume. The overall cast aluminum structure is stable, which fully ensures the high-speed movement of the equipment and the accuracy requirements during high-speed movement.

Applicable materials:

It can cut a variety of metal plates and tubes, and is mainly suitable for fast cutting of stainless steel, carbon steel, galvanized sheet, various alloy sheets, rare metals and other materials.

Adapt to the industry:

Suitable for aerospace technology, aircraft manufacturing, rocket manufacturing, robot manufacturing, elevator manufacturing, ship manufacturing, sheet metal cutting, kitchen furniture, auto parts, heat dissipation and ventilation ducts, chassis cabinets, kitchen cabinets, machinery manufacturing, etc. Sheet metal industry.

This is David from triumphlaser,if you have any questions about triumphlaser, just feel free to contact me.I will always here being ready to offer help.

Email:david@triumphlaser.com