Technical analysis of laser cutting aluminum

From the perspective of cost and investment, the widely used aluminum laser cutting equipment is fiber laser cutting machine and YAG laser cutting machine, both of which are cutting aluminum or cutting other materials, such as stainless steel, carbon steel, etc. Decent performance.

Judging from the experience of laser cutting aluminum materials for many years, the difference between the two is still large. It can be divided into three levels, one is the quality of the cutting, the other is the cutting speed, and the third is the production cost (the production cost here is mainly only Life loss of equipment).

1. Cutting quality

Aluminum profile is a highly reflective material, so neither fiber laser cutting machine nor YAG laser cutting machine can process thicker aluminum. In addition, aluminum materials are not resistant to high temperatures, and burrs are prone to appear in the process of cutting aluminum materials. Therefore, it is necessary to focus on the control process to obtain the ideal cutting quality.

2. Cutting speed

The cutting speed also needs to be controlled. Too fast cutting speed is prone to burrs, and too slow cutting speed will cause cracks in aluminum materials, which will affect the cutting quality, so process control is required. Generally speaking, the cutting speed of fiber laser cutting machine is higher than that of YAG laser cutting machine for laser cutting equipment with the same power.

3. Production cost

The processing cost of laser cutting machine is very low, far lower than other cutting processes. As a comparison between fiber laser cutting machine and YAG laser cutting machine, the cost of fiber laser cutting is lower than that of YAG laser cutting machine. The latter requires frequent replacement of laser lamp accessories. However, from a long-term perspective, aluminum material is better for fiber laser cutting machine The damage of the laser is more serious, which greatly reduces the life of the laser. From this point of view, YAG is lower than the cost of fiber laser cutting machine.

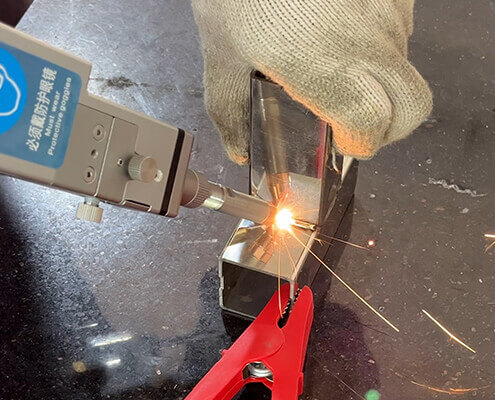

4. Triumphlaser uses nlight laser source, which can perfectly solve the damage caused by high reflective materials such as aluminum, copper, gold and silver to the laser, prolong the life of the laser source , and is suitable for almost all kinds of metals.

Another thing to note is that aluminum has high reflectivity and low absorption of laser light, so you need to wear laser protective glasses during processing to protect yourself.

This is David from triumphlaser,if you have any questions about triumphlaser, just feel free to contact me.I will always here being ready to offer help.

Email:david@triumphlaser.com