How to improve the welding speed of laser welding machine?

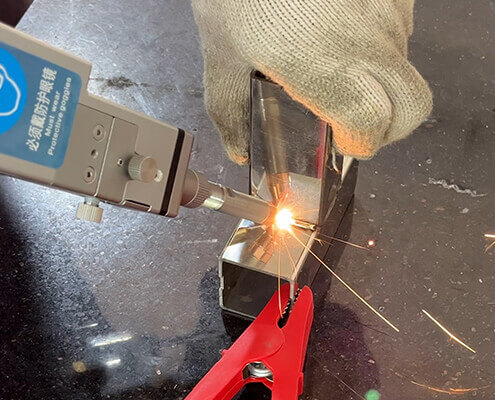

The purpose of the fiber laser welding machine is to bring higher production efficiency to the enterprise and create higher value, so how to increase the welding speed of the fiber laser welding machine? Triumph Laser will talk to you about the factors that affect the welding speed?

There are three main parameters that affect the welding speed, laser power, welding speed, defocus, and other parameters are protection or side blowing gas flow.

If you are in the initial stage of exploring welding process parameters, it is best to choose the single-variable control method. During welding, the defocus amount will remain unchanged after finding a suitable value. The laser power and welding speed are mainly adjusted, because the weld formation is generally mainly It is determined by both the laser power and the welding speed, which means that the two parameters need to form an appropriate welding process parameter window.

- The main factors affecting the welding speed of fiber laser welding machine are divided into internal factors and processing workpieces.

The internal factors are mainly laser frequency, laser spot mode and beam divergence angle, laser power, reasonable optical shaping and auxiliary gas and material during processing. The internal factors are mainly paid attention to when choosing the model in the early stage, and you should follow the advice of the laser engineer to purchase. Another factor that the customer needs to pay attention to during processing is the welding density, welding width, welding depth and laser spot size.

2. Welding depth

According to demand, if the welding depth needs to be deepened, the parameters of the fiber laser welding machine need to be adjusted, and the power and current of the fiber laser welding machine should be increased. Therefore, the marking speed will be affected in these processes.

3. Laser spot size

The smaller the light spot corresponds to the smaller the marking volume, therefore, the larger the light spot, the faster the marking speed.

4, welding density

In the case of the same format, the same spot, and the same depth, the higher the welding density, the slower the corresponding welding speed. The reason is that the density directly increases the welding area.

5. Welding format

Because the deflection area of the large-format welding galvanometer is enlarged, the welding speed of large-format welding is slower than that of small-format welding.

The above are the techniques to increase the welding speed of the fiber laser welding machine. I believe that if you follow these methods, you can increase the welding speed and create higher benefits.

The laser welding machine produced by Triumph has a complete range of styles and models. Triumph laser provides free samples to customers and selects the most suitable laser welding machine for customers.

This is Yolanda from triumphlaser If you want to learn more about laser cutting machine, please don’t hesitate to contact with me.

Email:sales1@triumphlaser.com

triumphlaser

triumphlaser

triumphlaser

triumphlaser