Working Principle and Applications of Laser Welding Machines

Laser welding machines are high-precision and efficient welding devices, operating based on the following principles:

- Laser Generation: A laser generator produces a high-energy laser beam.

- Beam Transmission: The laser beam is transmitted to the welding area through components like optical fibers or mirrors.

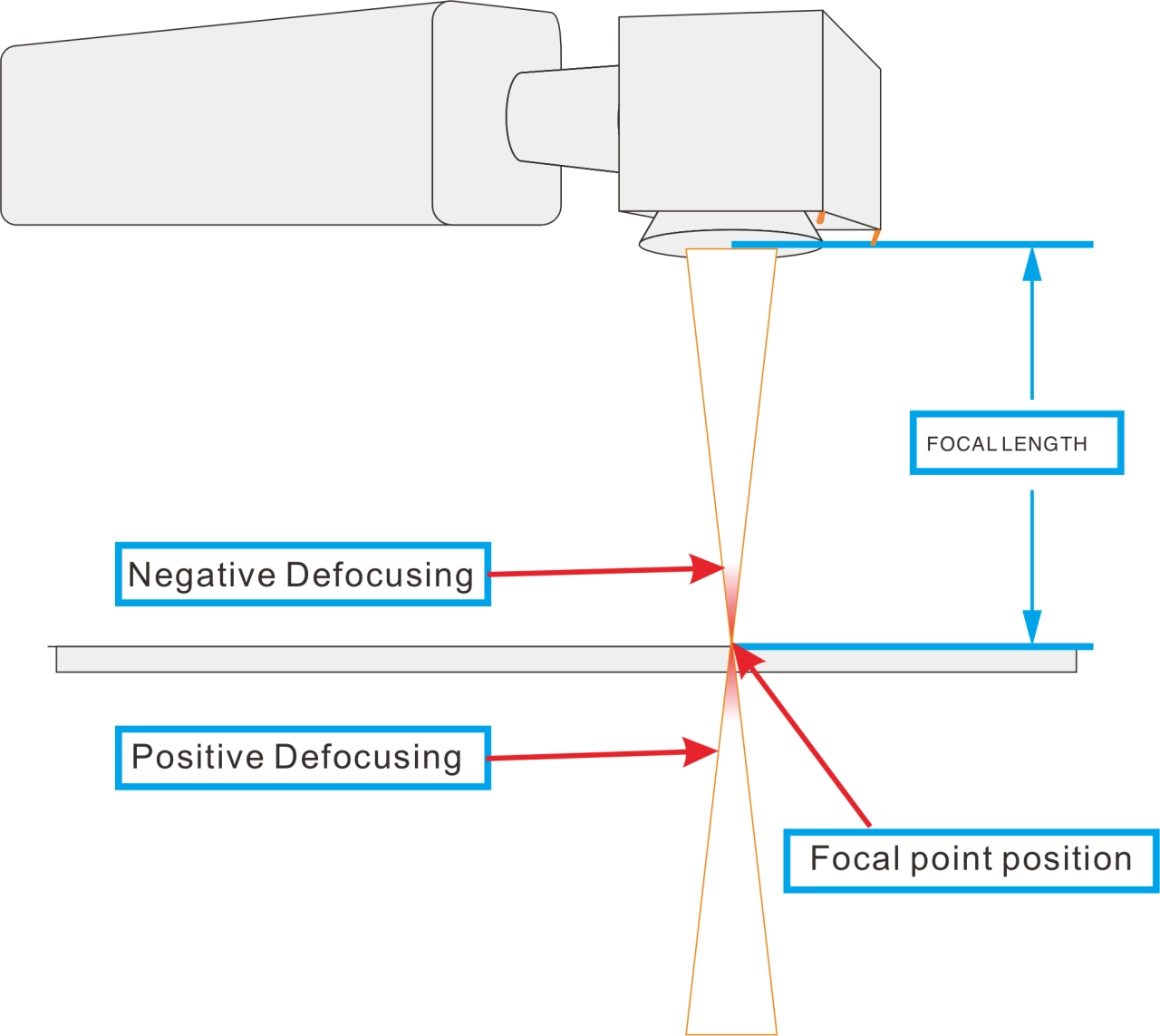

- Focusing: The beam is focused onto the welding point, creating a high-energy density spot.

- Welding Process: The high-energy laser beam rapidly heats the welding material, achieving welding connection.

Laser welding machines find wide applications in various industries[5], including:

- Aerospace: Used for welding components in aerospace engines and structures.

- Automotive Manufacturing: Applied in welding car bodies, chassis, and other parts.

- Electronics and Telecommunications: Utilized for precise welding of microelectronic devices and communication equipment.

- Medical Devices: Employed in the fine welding of medical instruments, including assembly of implantable medical devices.

- Mold Processing: Used for mold repair and manufacturing.

Laser welding machines, with their advantages of fast welding speed, small heat-affected zone, low distortion, and high weld seam quality, play a significant role in modern manufacturing..

This is selina from triumphlaser If you want to learn more about laser welding machine, please don’t hesitate to contact with me.

Email:selina@triumphlaser.com

triumphlaser

triumphlaser